تسجيل الدخول أو إنشاء حساب

Closeالزبون العائد

أنا زبون عائد

تسجيل الدخول أو إنشاء حساب

Closeتسجيل حساب

إذا كان لديك بالفعل حساب معنا ، يرجى تسجيل الدخول على نموذج تسجيل الدخول.

لقد تم انشاء الحساب بنجاح !

شكراً على التسجيل في موقع Egyptlifts!

سيتم إعلامك عن طريق البريد الإلكتروني عندما يتم تفعيل حسابك من قبل فريق عمل الموقع.

إذا كانت لديك استفسارات عن نظام عمل الموقع، يرجى الاتصال بفريق عمل الموقع.

خروج

تم تسجيل خروجك من الحساب. يمكنك مغادرة الموقع بأمان

سلة التسوق الخاصة بك قد تم حفظها، الطلبات الموجودة في السلة سوف يتم استعادتها كلما قمت بتسجيل الدخول إلى حسابك.

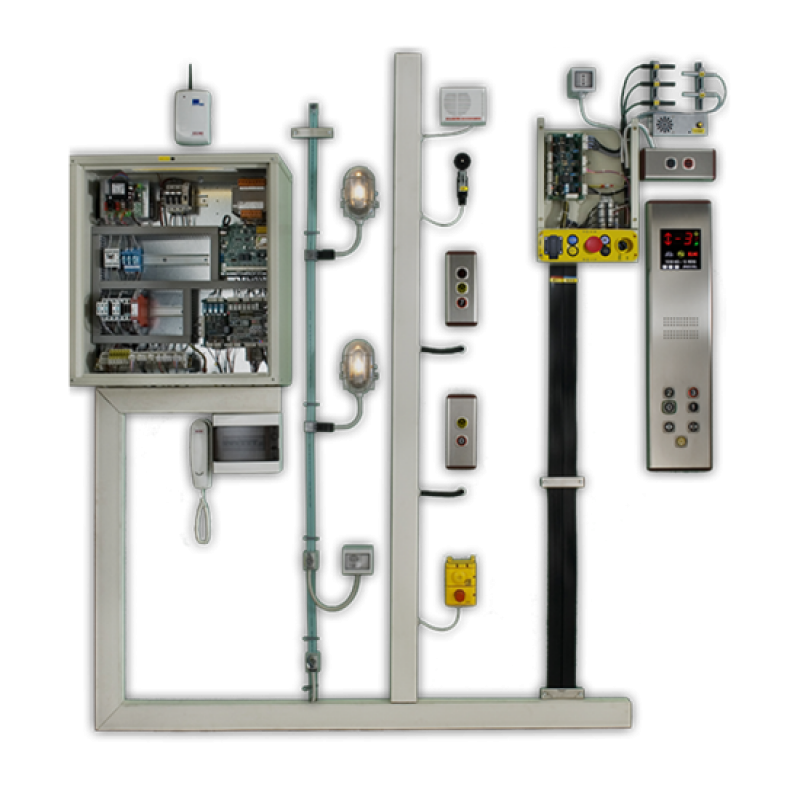

مهمات مرحلة الكهرباء للمصاعد

مهمات مرحلة الكهرباء للمصاعد

مرحلة الكهرباء للمصاعد تشير إلى الجانب الهندسي والتقني الذي يرتبط بنظم الكهرباء المستخدمة في تشغيل المصاعد. يتطلب تصميم وصيانة المصاعد الكثير من التخصص في مجال الكهرباء، حيث تعد هذه الجوانب أساسية لضمان سلامة وكفاءة تشغيل الاسانسير. إليك تعريف مهمات مرحلة الكهرباء للمصاعد. (ليفت)

توليد الحركة ( مهمات مرحلة الكهرباء للمصاعد)

توليد الحركة في مرحلة الكهرباء للمصاعد يمثل جزءًا أساسيًا من عملية تشغيلها. يتم تحقيق توليد الحركة عن طريق الاستفادة من نظام كهربائي يتحكم في المحركات الموجودة في الآلية الرئيسية للمصعد. يعتبر المحرك هو المكون الرئيسي الذي يحول الطاقة الكهربائية إلى حركة ميكانيكية، ويكمن دوره الأساسي في رفع وخفض أسانسير بسلاسة وبدقة. (اسنسير)

المحرك يعتمد على تفاعل الحقل المغناطيسي

والتيار الكهربائي لتحريك الأجزاء المتحركة داخل اسانسيرعند توصيل التيار

الكهربائي بالمحرك، يتولد حقل مغناطيسي يتفاعل مع الأجزاء المغناطيسية الأخرى في

المحرك، مما يؤدي إلى حدوث حركة دورانية. يتم توجيه هذه الحركة لتحريك البكرات

والكوابل المتصلة بالمصعد، وهكذا يتم تحقيق عملية الرفع أو الخفض بشكل كفء. ( مهمات مرحلة الكهرباء للمصاعد) (الاسناسير)

تحظى عملية توليد الحركة بأهمية كبيرة، حيث يتطلب الأمر دقة عالية في التحكم لضمان رحلات آمنة وسلسة للمصعد. تقنيات توليد الحركة المستخدمة في اليوم الحالي تعكس تقدمًا تكنولوجيًا مستمرًا، مع تطوير محركات فعالة وقابلة للتحكم بدقة، مما يسهم في تعزيز كفاءة الطاقة وتحسين تجربة المستخدمين. (الأسانسير)

أنظمة التحكم ( مهمات مرحلة الكهرباء للمصاعد)

أنظمة التحكم تشكل عنصرًا حيويًا في مرحلة

الكهرباء للمصاعد، حيث تلعب دورًا رئيسيًا في ضمان تشغيل المصعد بشكل فعال وآمن.

يعتمد تصميم هذه الأنظمة على تكنولوجيا متقدمة للتحكم في جميع جوانب حركة المصعد،

بدءًا من البداية وحتى الوصول إلى الهدف المطلوب.

تتضمن أنظمة التحكم عدة عناصر، منها لوحات

التحكم الرئيسية والبرمجيات المتقدمة، التي تمكن من ضبط سرعة مصاعد، وتحديد

التسارع والتباطؤ بدقة، وضمان وقوف مصعد بشكل أمن في الأدوار المختلفة. كما تتيح

هذه الأنظمة أيضًا التفاعل مع أجهزة الاستشعار والمستشعرات للتحقق من وجود

المستخدمين والتأكد من سلامتهم.

( مهمات مرحلة الكهرباء للمصاعد)

تكنولوجيا التحكم الحديثة تستفيد من أنظمة الأتمتة والذكاء الاصطناعي لتعزيز أداء المصاعد. تحديثات البرمجيات المنتظمة تسمح بتحسين وتعديل وظائف التحكم وفقًا لمتطلبات الاستخدام والتطورات التكنولوجية. (تركيب اسانسير بالتقسيط)

توفير نظام تحكم فعّال يسهم في تحسين كفاءة

الطاقة وتوفيرها، كما يعزز الأمان والأداء العام للمصعد. يعكس التقدم المستمر في

هذا المجال التفاني في تقديم تجارب تشغيل مصاعد ذكية ومبتكرة، مما يعزز الراحة

والسلامة للمستخدمين.

( مهمات مرحلة الكهرباء للمصاعد) (تركيب المصاعد)

الكوابل والأسلاك

تكمن أهمية الكوابل والأسلاك في مرحلة

الكهرباء للمصاعد في توفير وسيلة فعّالة لنقل الطاقة الكهربائية بين مختلف

المكونات الكهربائية داخل المصعد. يتم استخدام الكوابل لربط الكتل والأجزاء الميكانيكية

مع المحركات ولوحات التحكم الكهربائية، مما يسهم في تحقيق حركة دقيقة وسلسة للمصعد. ( مهمات مرحلة الكهرباء للمصاعد)

توفير كوابل عالية الجودة يعزز من كفاءة نقل الطاقة ويسهم في تحقيق أداء مستقر للمصعد. يجب أن تكون هذه الكوابل قادرة على تحمل الأحمال الثقيلة وظروف الاستخدام المتكررة دون تأثير سلبي على كفاءتها. يتعين أيضًا على هذه الكوابل أن تكون متينة ومقاومة للتآكل والتلف لضمان السلامة والأداء الطويل الأمد. (تركيب المصعد)

أما بالنسبة للأسلاك، فتلعب دورًا مهمًا في

نقل التيار الكهربائي من لوحات التحكم إلى المحركات والأجهزة الكهربائية الأخرى.

يتم اختيار الأسلاك بعناية لضمان توصيل فعّال للطاقة دون فقدان كبير في الجهد

الكهربائي. يجب أن تكون هذه الأسلاك عازلة بشكل جيد لتجنب حدوث تسربات كهربائية

وضمان سلامة المصعد والمستخدمين.

( مهمات مرحلة الكهرباء للمصاعد) (تعليمات استخدام المصاعد)

تتطلب الكوابل والأسلاك في مصاعد اليوم تقنيات متطورة ومواد عالية الجودة لضمان استمرارية العمل وتلبية معايير السلامة والأداء. استثمار في تلك العناصر يسهم بشكل كبير في تحسين الكفاءة والموثوقية لنظام المصعد. (سعر جهاز الطوارئ للمصاعد)

صيانة المكونات الكهربائية ( مهمات مرحلة الكهرباء للمصاعد)

صيانة المكونات الكهربائية تشكل جزءًا حيويًا في الحفاظ على أداء المصاعد وضمان سلامتها. يتطلب الحفاظ على المكونات الكهربائية دوريًا وعناية خاصة لضمان استمرارية تشغيل المصعد بكفاءة. يشمل ذلك عدة جوانب: (سعر جهاز الطوارئ للمصاعد في مصر)

أولاً وقبل كل شيء، يتعين على الفنيين

المختصين إجراء فحص دوري للمكونات الكهربائية، مثل لوحات التحكم والمفاتيح

والمحركات. يتم خلال هذا الفحص التحقق من سلامة الاتصالات والأسلاك واكتشاف أي

تلفيات قد تؤثر على أداء المصعد.

( مهمات مرحلة الكهرباء للمصاعد)

يجب أيضًا فحص المفاتيح والمستشعرات المختلفة المتواجدة في المصعد للتأكد من أنها تعمل بشكل صحيح. يشمل ذلك فحص أجهزة الاستشعار للأبواب والأجهزة الكهربائية المتعلقة بالسلامة للتأكد من استجابتها السليمة في حالات الطوارئ. (سعر كالون باب مصعد)

تشمل صيانة المكونات الكهربائية أيضًا

التحقق من حالة الكوابل والأسلاك. يجب فحصها بانتظام للتأكد من خلوها من التلف أو

التآكل، مما يساعد في تجنب حوادث الكهرباء أو انقطاع التيار. ( مهمات مرحلة الكهرباء للمصاعد)

عند اكتشاف أي عيب أو تلف في المكونات الكهربائية، يجب إجراء الإصلاحات الضرورية على الفور. قد تشمل هذه الإصلاحات استبدال الأجزاء التالفة أو تحديث الأنظمة القديمة بتقنيات أحدث وأكثر فعالية. (صور مصاعد)

في الختام، يعتبر الاهتمام بصيانة المكونات

الكهربائية للمصاعد استثمارًا حكيمًا لضمان استدامة الأداء العالي والتشغيل الآمن

للمصاعد، وهو جزء أساسي من جهود الحفاظ على البنية التحتية للمباني.( مهمات مرحلة الكهرباء

للمصاعد)

تحكم عن بُعد

تكنولوجيا التحكم عن بُعد تمثل نقلة نوعية في مجال صناعة المصاعد، حيث تسهم في تحسين تجربة المستخدمين وتعزيز الراحة والكفاءة. يُعتبر التحكم عن بُعد وسيلة مبتكرة لتمكين المستخدمين من التفاعل مع المصاعد بطريقة مريحة وفعالة، سواء كانوا داخل المبنى أو حتى عن بُعد. (تعليمات استخدام المصعد)

تُتيح تقنيات التحكم عن بُعد للمستخدمين

استخدام وحدة تحكم أو تطبيق على الهاتف الذكي لطلب المصعد أو التحكم في اتجاهاته.

هذا يعزز الفاعلية ويقلل من وقت الانتظار، حيث يمكن للمستخدمين طلب المصعد في

الوقت المناسب لهم دون الحاجة إلى الانتظار في الرواق أو عند الباب. ( مهمات مرحلة الكهرباء للمصاعد)

في إضافة إلى الراحة، تساهم تقنيات التحكم عن بُعد في تعزيز السلامة، حيث يمكن للمستخدمين استخدام الأجهزة الخاصة بهم لتفعيل وحدات الطوارئ أو الاتصال بفرق الصيانة في حالات الطوارئ. (صيانة مصعد)

تجسيد تقنيات التحكم عن بُعد في نظم المصاعد

يُظهر التطور المستمر في مجال الهندسة وتكنولوجيا المباني، حيث يتم توظيف هذه

التقنيات لتحقيق أداء مصاعد أكثر ذكاءً وفاعلية، مما يعكس التزام الصناعة بتلبية

توقعات المستخدمين المتزايدة وتحسين تجربتهم في الأبنية المختلفة. ( مهمات مرحلة الكهرباء للمصاعد)

تقنيات الأتمتة ( مهمات مرحلة الكهرباء للمصاعد)

تقنيات الأتمتة تمثل جوانبًا أساسية في

تحسين أداء وفعالية مصاعد اليوم. تهدف هذه التقنيات إلى جعل عمليات التشغيل أكثر

ذكاءً وسلاسة، مما يسهم في تحسين تجربة المستخدمين وتقليل الأعطال الناتجة عن

التدخل البشري. تشمل هذه التقنيات عدة جوانب مهمة:

أولًا، نجد تقنيات الأتمتة تُدمج بشكل كبير

في نظم التحكم الذكية، حيث يتم استخدام أجهزة الاستشعار وأنظمة الرصد لتتبع حالة

المصعد بشكل دائم. يمكن لهذه التقنيات الاستجابة السريعة للظروف المتغيرة وتعديل

التشغيل بمرونة لتحسين أداء المصعد.

( مهمات مرحلة الكهرباء للمصاعد)

ثانيًا، تشمل تقنيات الأتمتة استخدام أنظمة

التحكم في الطاقة لتحسين كفاءة استهلاك الطاقة. يُمكن برمجة المصاعد بشكل دقيق

لتحقيق توازن بين الأداء الفعال وتوفير الطاقة، مما يسهم في الاستدامة البيئية

وتقليل التأثير البيئي.

ثالثًا، تقنيات الأتمتة تشمل نظم التشخيص

الذاتي، حيث يتم استخدام البرمجيات المتطورة للكشف عن أي مشكلات محتملة في وقت

مبكر. يتيح هذا النهج للفحص الدوري والصيانة الوقائية، مما يساعد في تجنب التوقفات

غير المخططة ويحسن من موثوقية المصاعد.

أخيرًا، يتيح الاتصال الذكي وتكنولوجيا

الإنترنت للمصاعد التواصل مع أنظمة الصيانة وفرق الدعم عن بُعد. يمكن رصد أداء

المصعد والتشخيص عن بُعد، مما يساعد في تقديم الصيانة الفورية وتقليل فترات التوقف

غير المخططة.

(مهمات مرحلة الكهرباء للمصاعد)

في الختام، تُظهر تقنيات الأتمتة في مجال المصاعد

التطور المستمر نحو مستقبل أكثر ذكاءً وكفاءة، حيث تلبي هذه الابتكارات توقعات

المستخدمين وتعزز الأمان والأداء الشامل للمصاعد.

التحكم في السرعة والتسارع

تحكم في السرعة والتسارع يعتبران جوانبًا

حيوية في تصميم وعمل مصاعد اليوم، حيث يتيح هذا التحكم تحقيق رحلات آمنة وسلسة

للمصعد. يتطلب تصميم متقدم لأنظمة التحكم تحديد دقيق للسرعة والتسارع لتلبية

احتياجات الركاب وضمان سلامتهم.

فيما يتعلق بالسرعة، يجب ضبطها بعناية

لضمان رحلة سلسة ومريحة للمستخدمين. يمكن تحديد السرعة بشكل دقيق لضمان توفير وقت

الانتظار وتحسين كفاءة النقل الرأسي في المبنى. بالإضافة إلى ذلك، يسهم التحكم في

السرعة في تقليل استهلاك الطاقة وتحسين الأداء العام للمصعد.

أما التحكم في التسارع، فيلعب دورًا حيويًا

في توفير تجربة استخدام خالية من الاهتزازات الزائدة والتسارعات الغير مرغوب فيها.

يتيح التحكم الدقيق في التسارع تجنب الاهتزازات الزائدة أثناء بداية الحركة

والتوقف، مما يسهم في راحة المستخدمين ويقلل من الضغط على هيكل المصعد.

باستخدام تقنيات التحكم في السرعة

والتسارع، يمكن تحقيق توازن فعال بين الأداء الديناميكي والراحة، مما يجعل استخدام

المصاعد أكثر أمانًا واستدامة. هذا التحكم الدقيق يمثل عنصرًا مهمًا في تطوير

وتحسين تكنولوجيا المصاعد لتلبية تطلعات المستخدمين الحديثة وتحسين تجربتهم.

السلامة الكهربائية

السلامة الكهربائية تعد جانبًا حيويًا في

تصميم وتشغيل مصاعد اليوم، حيث تعتمد سلامة الكهرباء على اتخاذ إجراءات وتقنيات

متقدمة لضمان حماية المستخدمين ومنع حوادث الكهرباء. يتطلب تصميم النظم الكهربائية

في المصاعد الامتثال لمعايير السلامة واستخدام تقنيات حديثة لتحقيق أقصى درجات

الأمان.

أحد جوانب السلامة الكهربائية يتعلق بالعزل

الجيد واستخدام مواد عازلة عالية الجودة لتفادي تسرب التيار الكهربائي وحماية

المستخدمين من التماسات الكهربائية. تشمل هذه التقنيات أيضًا استخدام أجهزة

الحماية من التيار الزائد والتيار القصير لتفادي حدوث أعطال كهربائية غير مرغوب

فيها.

تقنيات الكشف عن أخطاء الكهرباء تلعب أيضًا

دورًا هامًا في تحسين السلامة، حيث يتم استخدام أنظمة متقدمة لرصد أي انحراف في

التيار الكهربائي أو أي مشكلة تقنية قد تؤدي إلى خلل في النظام.

إضافة إلى ذلك، يشمل السلامة الكهربائية توفير تدريب مستمر للفنيين المعنيين بصيانة المصاعد لضمان تعاملهم الآمن مع الأنظمة الكهربائية. يجب عليهم فهم كل تفاصيل الأنظمة الكهربائية واتخاذ الإجراءات الوقائية اللازمة لتجنب المخاطر

مهمات مرحلة كهرباء كاملة - ELMI

EGP81.00

السابق الضرائب: EGP81.00

مهمات مرحلة كهرباء كاملة - ELMI مهمات مرحلة الكهرباء الكاملة للمصعد من شركة ELMI تشمل مجموعة من العناصر والمكونات الكهربائية التي تستخدم لتشغيل وتحكم في محرك المصعد وأنظمته الكهربائية. هذه المكونات تضمن تشغيل المصعد بشكل آمن وفعال. بما أن مراحل ..

حالة التوفر:متوفر

.jpg)