تسجيل الدخول أو إنشاء حساب

Closeالزبون العائد

أنا زبون عائد

تسجيل الدخول أو إنشاء حساب

Closeتسجيل حساب

إذا كان لديك بالفعل حساب معنا ، يرجى تسجيل الدخول على نموذج تسجيل الدخول.

لقد تم انشاء الحساب بنجاح !

شكراً على التسجيل في موقع Egyptlifts!

سيتم إعلامك عن طريق البريد الإلكتروني عندما يتم تفعيل حسابك من قبل فريق عمل الموقع.

إذا كانت لديك استفسارات عن نظام عمل الموقع، يرجى الاتصال بفريق عمل الموقع.

خروج

تم تسجيل خروجك من الحساب. يمكنك مغادرة الموقع بأمان

سلة التسوق الخاصة بك قد تم حفظها، الطلبات الموجودة في السلة سوف يتم استعادتها كلما قمت بتسجيل الدخول إلى حسابك.

اعمده(دلائل) المصعد

اعمده-دليل- المصعد

تعد اعمده-دليل- المصعد من العناصر الأساسية في نظام مصاعد حديثة. تسهم

هذه الأعمدة بشكل كبير في ضمان عمليات الرفع بأمان وسلاسة. سنتعرف في هذا المقال

على دورها وأهميتها في عالم اسانسير.

تعريف اعمده-دليل- المصعد

تُعد "أعمدة دليل المصعد" عبارة عن هياكل رأسية مثبتة داخل حاوية مصعد والتي تؤدي دورًا حاسمًا في دعم وتوجيه حركة الكابينة أثناء الرفع والهبوط.

تعمل هذه الأعمدة على توجيه الحركة الرأسية للمصعد بطريقة سلسة وآمنة، مما يضمن

استقرار الكابينة وسلامة المسافرين. تتميز أعمدة دليل الأسانسير بتصميمها الخاص واستخدام

مواد متينة تضمن الأداء العالي والموثوقية في عملية الرفع والهبوط. تأتي أهمية هذه

الأعمدة في ضمان تجربة استخدام الاسناسير بأمان وكفاءة.

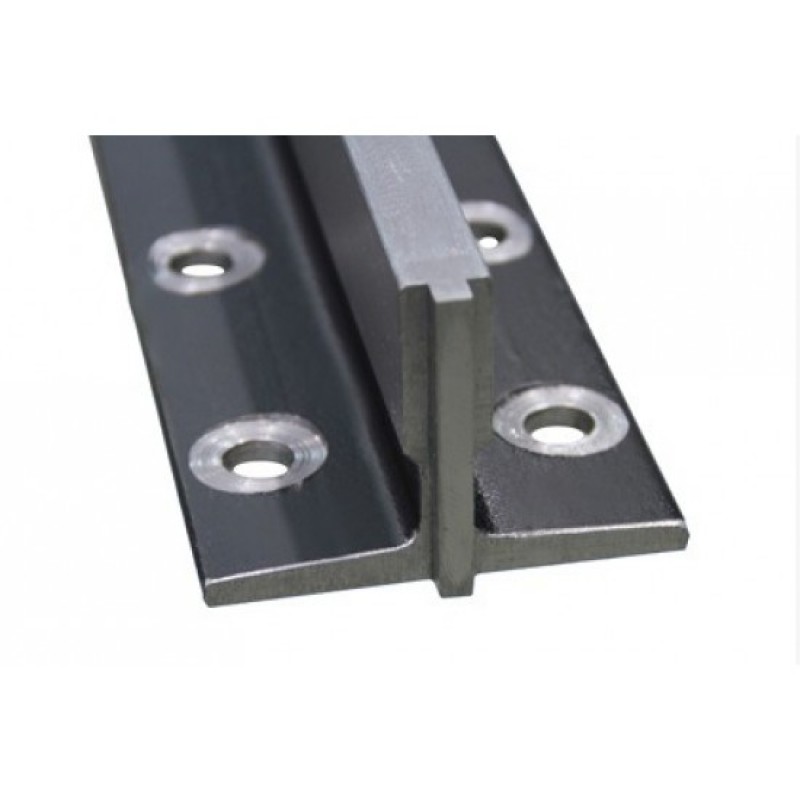

تصميم اعمده-دليل- المصعد

تصميم أعمدة دليل الاسانسير يعد عملية حساسة ومهمة لضمان أداء المصعد بأمان وكفاءة. يتم تصميم هذه الأعمدة بعناية لضمان تحملها للضغط والقوى التي تتعرض لها أثناء حركة المصعد. (كيف يمكنني استخدام أسانسير داخلي)

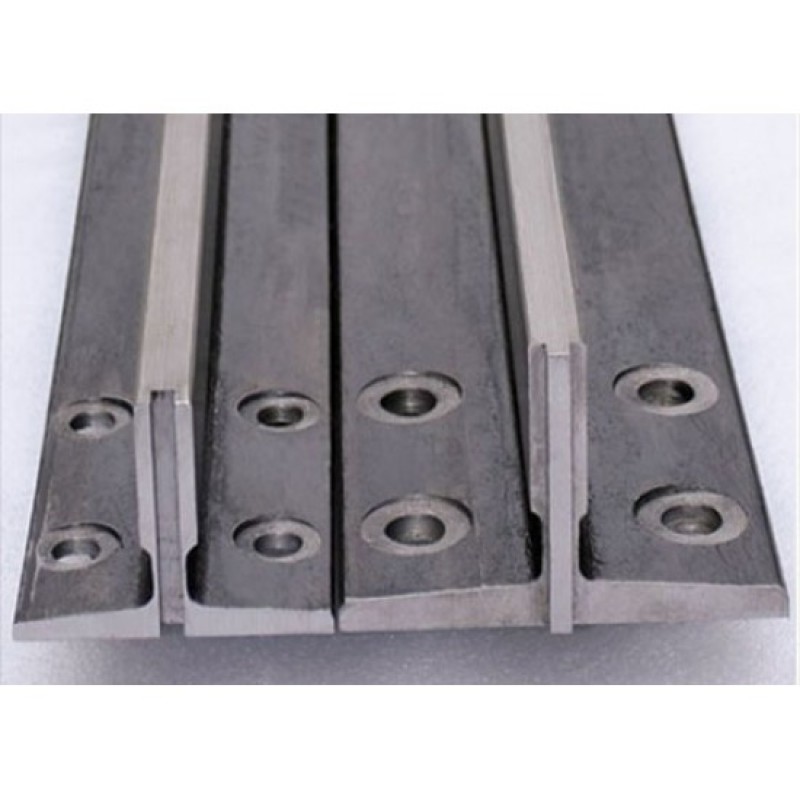

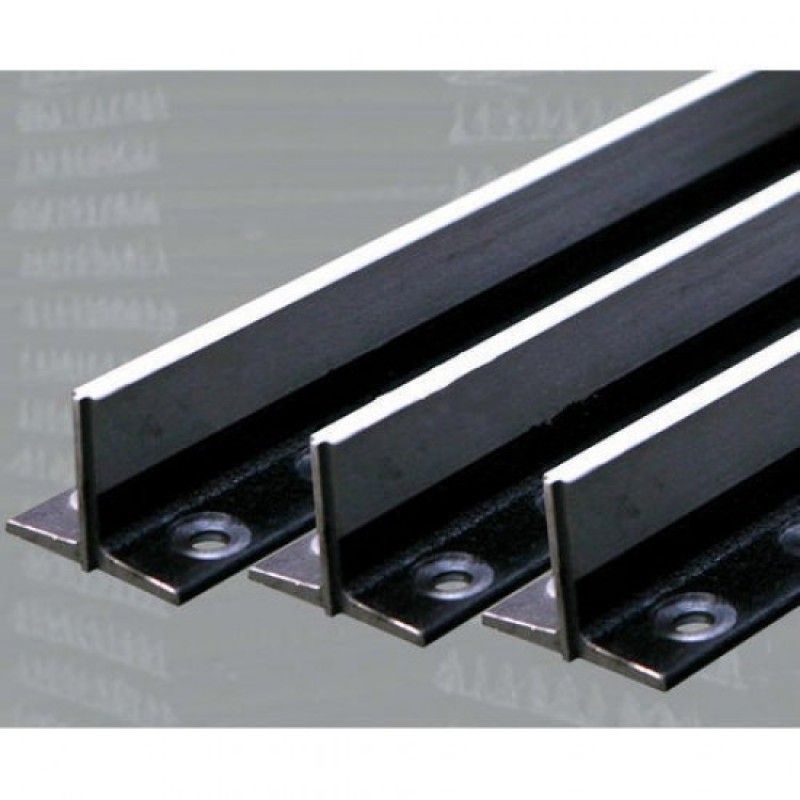

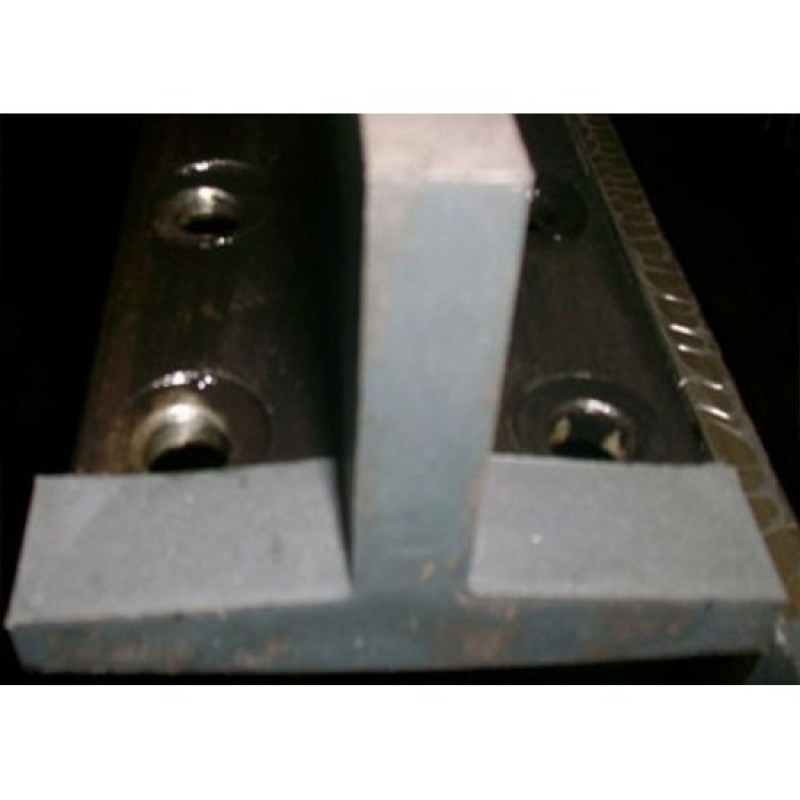

في التصميم الأساسي، تتألف اعمده-دليل- المصعد عادة من مواد معدنية متينة مثل الفولاذ أو الألومنيوم. تصمم هذه المواد بشكل استثنائي لتحقيق قوة عالية ومقاومة للتأثيرات البيئية والتآكل. يتم تشكيل الأعمدة بشكل أنبوبي أو مستطيل لتوفير هيكل متين يمكنه تحمل وزن المصعد والمسافرين. (كيفية اختيار أفضل المصعد الكهربائي للشراء)

بالإضافة إلى التصميم الهيكلي، تتضمن عملية التصميم أيضًا الأمور التقنية

مثل تحديد الأبعاد الدقيقة والتسامح والانتهاء من السطح. يجب أن يتم تصميم هذه

الأعمدة بدقة لضمان التوجيه الدقيق للمصعد والتقليل من الاهتزازات أثناء الحركة.

باختصار، تصميم اعمده-دليل- المصعد هو عملية شاملة تجمع بين الجوانب الهيكلية والتقنية لضمان أداء المصعد بأمان وفعالية على مدار الزمن. (كيفية فك شفرة أسانسير- طريقة عمل شفرة أسانسير)

المواد المستخدمة في صناعة اعمده-دليل- المصعد

تعتمد صناعة أعمدة دليل المصعد على استخدام مواد عالية الجودة تمتاز بمقاومتها للتأثيرات الميكانيكية والتآكل والتأكد من أداء المصعد بأمان وثبات. الأمثلة التالية تُظهر بعض المواد الشائعة المستخدمة في صناعة أعمدة دليل المصعد: (ما هو أرخص مصعد كهربائي في مصر)

· الفولاذ المقاوم للصدأ (Stainless Steel): يعتبر الفولاذ المقاوم للصدأ مادة شائعة في صناعة أعمدة المصاعد نظرًا لمقاومته العالية للصدأ والتآكل. يتميز بمتانته وقوته، مما يجعله خيارًا مثاليًا لأعمدة دليل المصاعد. (ما هو انفرتر مصاعد وأهم فوائده)

· الألومنيوم (Aluminum): يتميز الألومنيوم بوزنه الخفيف مقارنة بالفولاذ، مما يساهم في تقليل وزن هيكل المصعد بشكل عام. يتم استخدام الألومنيوم على نطاق واسع في تصنيع اعمده-دليل- المصعد للمصاعد ذات الاحمال الخفيفة إلى المتوسطة. (ماكينة ايطالي جيد)

· الكربون الصلب (Carbon Steel): يُستخدم الكربون الصلب لصناعة أعمدة المصاعد التي تحتاج إلى متانة وصلابة عالية. يعتبر هذا النوع من الفولاذ مناسبًا للمصاعد ذات الأحمال الثقيلة. (مصاعد مستعملة للبيع في مصر)

· الألياف الزجاجية (Fiberglass): تُستخدم الألياف الزجاجية أحيانًا في مصاعد المباني ذات البيئات القاسية أو حيث يكون الوزن مهمًا للغاية. إنها تمتاز بخفة وزنها ومقاومتها للتآكل. (مصاعد هاي ليفت- اسعار مصاعد كهربائية في مصر)

تُختار المادة المناسبة حسب متطلبات المشروع وتحميل المصعد والبيئة المحيطة به. تضمن هذه المواد القوة والاستدامة والأمان لاعمده-دليل- المصعد، مما يساهم في تحقيق أداء موثوق به للمصعد على مدى فترة طويلة من الزمن. (أخر أسعار أٍسانسير هيدروليك)

دور اعمده-دليل- المصعد

دور أعمدة دليل المصعد أساسي وحيوي في عملية رفع وهبوط المصعد وضمان سلامة وكفاءته. إليك فقرة توضح دور أعمدة دليل المصعد بشكل أكثر تفصيلاً: (أسانسيرات- أسانسير- مصعد- مصاعد)

اعمده-دليل- المصعد تمثل العمود الفقري لهذه الأجهزة الحديثة، حيث تقوم بدور حيوي في توجيه واستقرار الحركة الرأسية للمصعد. تعمل هذه الأعمدة على توجيه كابينة المصعد والتحكم في اتجاه حركتها بشكل دقيق وسلس. عندما يتم تشغيل المصعد ويبدأ في الصعود أو الهبوط، تكون هذه الأعمدة هي المسؤولة عن توجيه الكابينة بأمان وبدون اهتزازات غير مرغوب فيها.

إلى جانب توجيه الحركة، تلعب اعمده-دليل- المصعد دورًا كبيرًا في استقرار المصعد. فهي تعمل على تقليل أي اهتزازات غير مرغوب فيها أثناء الرفع والهبوط، مما يؤدي إلى توفير تجربة سفر مريحة وآمنة للركاب. تصمم هذه الأعمدة بدقة لتحمل الأحمال الزائدة والضغوط الميكانيكية التي تمارس عليها أثناء التشغيل اليومي للمصعد. (أسعار الأسانسير في مصر)

باختصار، دور أعمدة دليل المصعد يتجاوز الدعم البسيط ويمتد إلى تحقيق سلامة واستقرار المصعد وتأمين تنقل سلس وفعال داخل المبنى. (أسعار المصاعد الهيدروليك)

أنواع اعمده-دليل- المصعد

هناك عدة أنواع مختلفة من اعمده-دليل- المصعد تستخدم حسب احتياجات وظروف

التركيب. فيما يلي فقرة تشرح بإيجاز بعض الأنواع الشائعة لأعمدة دليل المصعد:

1. أعمدة دليل الفولاذ (Steel Guide Rails): تعتبر أعمدة دليل الفولاذ من الأنواع الأكثر شيوعًا واستخدامًا في صناعة المصاعد. تُصنع هذه الأعمدة عادةً من الفولاذ المقاوم للصدأ أو الفولاذ الكربوني، وتتميز بمتانتها وقدرتها على تحمل الأحمال الثقيلة. (أسعار المصاعد في مصر بالضمان)

2. أعمدة دليل

الألومنيوم (Aluminum Guide Rails): تُستخدم

اعمده-دليل- المصعد الألومنيوم بشكل شائع في المصاعد ذات الأحمال الخفيفة إلى

المتوسطة. الألومنيوم خفيف الوزن وقوي، مما يجعله مناسبًا للمصاعد الصغيرة

والمتوسطة الحجم.

3. أعمدة دليل

الكربون (Carbon Guide Rails): تُستخدم أعمدة

دليل الكربون عادةً في المصاعد ذات الأحمال الثقيلة. تمتاز هذه الأعمدة بمقاومتها

للتآكل وقدرتها على تحمل الأحمال الكبيرة، مما يجعلها خيارًا مناسبًا للمصاعد في

المباني الضخمة.

4. أعمدة دليل الألياف الزجاجية (Fiberglass Guide Rails): الألياف الزجاجية تُستخدم أحيانًا في المصاعد الخفيفة وفي البيئات التي تتعرض فيها الأعمدة للتآكل بشكل مكثف. تمتاز بخفة وزنها ومقاومتها للتآكل، وتكون مناسبة للمصاعد في الأماكن الساحلية أو المناطق الرطبة.

تختلف هذه الأنواع في المواد المستخدمة والتصميم والتحمل، ويتم اختيار نوع العمود الدليلي وفقًا لمتطلبات المشروع والظروف البيئية وحجم وحمولة المصعد.

صيانة واختبار اعمده-دليل- المصعد

صيانة واختبار اعمده-دليل- المصعد هي جزء حيوي من الحفاظ على أداء المصعد

بأمان وكفاءة على مر الزمن. تهدف هذه الصيانة إلى التحقق من سلامة واستدامة

الأعمدة، والكشف عن أي مشكلة محتملة قبل أن تتطور إلى مشكلة كبيرة تؤثر على أداء

المصعد. الصيانة تشمل عادة الخطوات التالية:

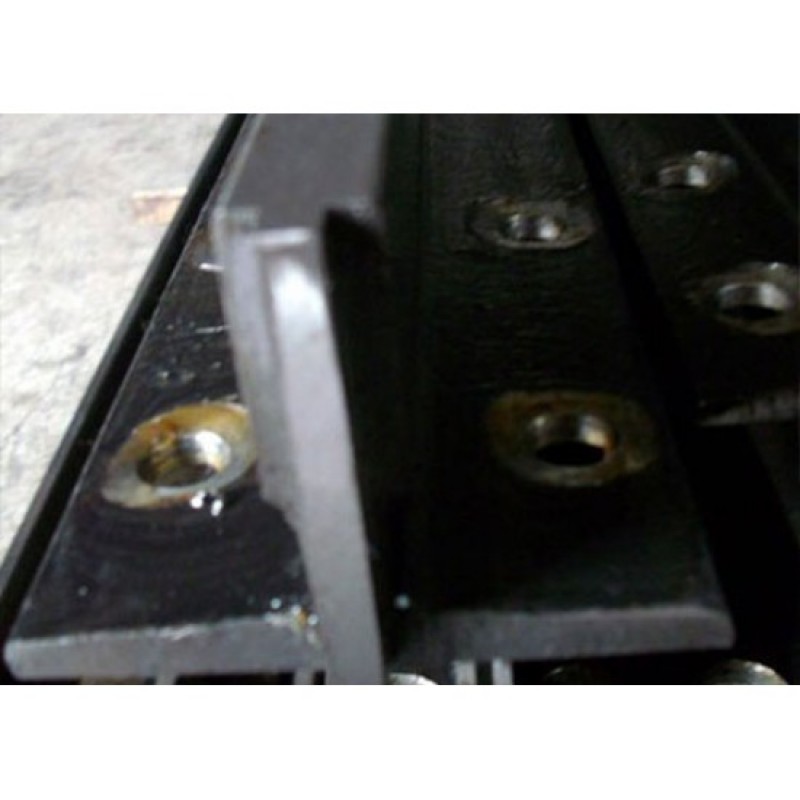

1. التفتيش

الدوري: يتضمن التفتيش الدوري فحص الأعمدة بشكل منتظم للتحقق من سلامتها. يجب فحص

السطوح والانتهاء من الأعمدة والتأكد من عدم وجود تآكل أو تلف.

2. التشحيم

والصيانة الوقائية: يجب توفير صيانة وقائية منتظمة بما في ذلك تشحيم المكونات

المتحركة في الأعمدة. هذا يساعد في تقليل الاحتكاك والتآكل، مما يزيد من عمر

الأعمدة ويحسن من أداء المصعد.

3. اختبار

الاستدامة: يجب إجراء اختبارات دورية للتحقق من استدامة الأعمدة وقدرتها على تحمل

الأحمال المختلفة. هذه الاختبارات تشمل اختبارات الشد والانحناء والاهتزازات.

4. اختبار

السلامة: يجب أيضًا إجراء اختبارات السلامة للتأكد من أن الأعمدة تلبي المعايير

الأمانية. هذا يشمل اختبارات مقاومة الحرائق واختبارات السلامة الكهربائية.

5. إصلاح العيوب:

إذا تم اكتشاف أي عيوب خلال عمليات الصيانة، يجب إصلاحها فورًا لضمان استمرارية

أمان وكفاءة المصعد.

صيانة واختبار أعمدة دليل المصعد هي عملية ضرورية للحفاظ على أمان المصعد

وتوفير أداء موثوق به. يجب أن تتم هذه الصيانة بانتظام وباستخدام مواد وتقنيات ملائمة

لضمان تشغيل المصعد بكفاءة على مر الزمن.

التحسينات الحديثة لاعمده-دليل- المصعد

التطورات التكنولوجية الحديثة قد أحدثت تحسينات كبيرة في مجال أعمدة دليل

المصعد، مما أسهم في تعزيز أداء وأمان هذه الأجزاء الحيوية لنظام المصعد. من بين

هذه التحسينات الحديثة:

1. تصميم هيكل

متطور: تم تطوير تصميم أعمدة دليل المصعد بحيث يتميز بقوة وصلابة أكبر مما كان

عليه في الماضي. هذا يعني أنه يمكن استخدام أعمدة أكثر نحافة وخفة وزنًا دون

التخلي عن قوتها، مما يوفر مساحة إضافية للكابينة ويزيد من كفاءة استخدام المصعد.

2. تقنيات التشحيم

المتطورة: تم تطوير تقنيات تشحيم متقدمة للأعمدة، مما يقلل من الاحتكاك ويزيد من

عمر المواد ويقلل من التآكل، مما يسهم في تحسين استدامة الأعمدة وتقليل الصيانة.

3. استخدام

المواد المبتكرة: تم تطوير مواد جديدة مثل الألياف الزجاجية المقواة والمواد

الكربونية لصناعة أعمدة دليل المصعد. هذه المواد تمتاز بخفة وزنها ومقاومتها

للتآكل، مما يزيد من أداء واستدامة الأعمدة.

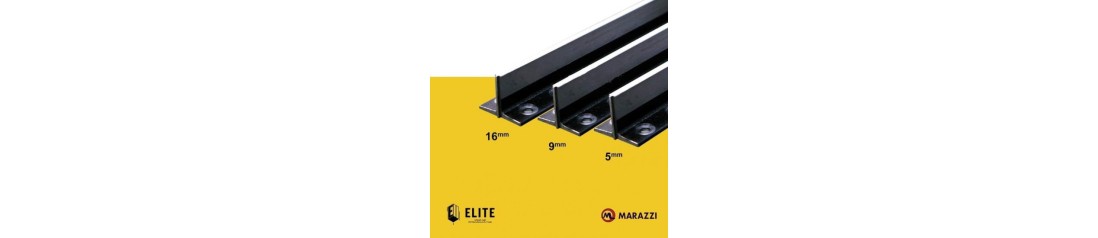

دليل 16 ملم - صيني سافيرا-89 × 62 × 16 ملم مع الفلنشـــة و المســــامير

EGP780.00

السابق الضرائب: EGP780.00

دليل 16 ملم - صيني سافيرا-89 × 62 × 16 ملم مع الفلنشـــة و المســــامير يبدو أنك تبحث عن دليل لحجم 16 ملم لصاج صيني سافيرا للمصعد بأبعاد 89 × 62 × 16 ملم، مع الفلنشة والمسامير. لكن للأسف، لا يمكنني توفير دليل محدد لهذه الطلبية بشكل مباشر، لأنني ..

حالة التوفر:متوفر

دليل 16 ملم - صيني سافيرا-90 × 62 × 16 ملم مع الفلنشـــة و المســــامير

EGP780.00

السابق الضرائب: EGP780.00

دليل 16 ملم - صيني سافيرا-90 × 62 × 16 ملم مع الفلنشـــة و المســــاميرأعتذر، لكنني لا يمكنني توفير دليل محدد بشكل فردي لمنتج معين، بما في ذلك الدليل الذي تبحث عنه لصاج صيني بحجم 16 ملم من نوع سافيرا بأبعاد 90 × 62 × 16 ملم مع الفلنشة والمسامير للمصع..

حالة التوفر:متوفر

دليل 16 مم إيطالي

EGP900.00

السابق الضرائب: EGP900.00

دليل 16 مم إيطالي أعتذر، ولكنني لا أملك وسيلة لتوفير دليل محدد بشكل فردي لمنتج معين بحجم 16 مم إيطالي للمصعد. يمكنك العثور على المعلومات التي تبحث عنها بمراجعة المواقع الرسمية للشركات المصنعة للمصاعد في إيطاليا أو البحث عبر الإنترنت باستخدام كلم..

حالة التوفر:متوفر

دليل 16 مم إيطالي عريض

EGP810.00

السابق الضرائب: EGP810.00

دليل 16 مم إيطالي عريض أعتذر، لا يمكنني توفير دليل محدد بشكل فردي لمنتج معين بحجم 16 مم إيطالي عريض للمصعد. يُفضل الاتصال بشركات متخصصة في صناعة وتوريد قطع المصاعد أو البحث عبر الإنترنت في مواقع الشركات المتخصصة للعثور على المعلومات الدقيق..

حالة التوفر:متوفر

دليل 16 مم إيطالي مرازي

EGP345.00

السابق الضرائب: EGP345.00

دليل 16 مم إيطالي مرازي أعتذر، ولكن لا يمكنني توفير دليل محدد بشكل فردي لمنتج معين بحجم 16 مم إيطالي مرازي للمصعد. يمكنك البحث عبر الإنترنت بواسطة محركات البحث بكلمات مثل "دليل 16 مم إيطالي مرازي للمصعد" للعثور على المعلومات التي تبحث عنها. يفضل..

حالة التوفر:متوفر

دليل 16 مم إيطالي مرازي

EGP900.00

السابق الضرائب: EGP900.00

دليل 16 مم إيطالي مرازي أعتذر، لكن لا يمكنني توفير دليل محدد بشكل فردي لمنتج معين بحجم 16 مم إيطالي مرازي للمصعد. يمكنك البحث عبر الإنترنت بواسطة محركات البحث بكلمات مثل "دليل 16 مم إيطالي مرازي للمصعد" للعثور على المعلومات التي تبحث عنها...

حالة التوفر:متوفر

دليل 16 مم إيطالي مونتفرو

EGP910.00

السابق الضرائب: EGP910.00

دليل 16 مم إيطالي مونتفرو أعتذر، ولكن لا يمكنني توفير دليل محدد بشكل فردي لمنتج معين بحجم 16 مم إيطالي مونتفرو للمصعد. يمكنك البحث عبر الإنترنت بواسطة محركات البحث بكلمات مثل "دليل 16 مم إيطالي مونتفرو للمصعد" للعثور على المعلومات التي تبحث عنها..

حالة التوفر:متوفر

دليل 16 مم تركي

EGP423.00

السابق الضرائب: EGP423.00

دليل 16 مم تركي أعتذر، ولكن لا يمكنني توفير دليل محدد بشكل فردي لمنتج معين بحجم 16 مم تركي للمصعد. يمكنك البحث عبر الإنترنت بواسطة محركات البحث بكلمات مثل "دليل 16 مم تركي للمصعد" للعثور على المعلومات التي تبحث عنها. يفضل مراجعة المواقع الرسمية ..

حالة التوفر:متوفر

دليل 16 مم تركي شاليكراي

EGP414.00

السابق الضرائب: EGP414.00

دليل 16 مم تركي شاليكراي أعتذر، ولكن لا يمكنني توفير دليل محدد بشكل فردي لمنتج معين بحجم 16 مم تركي شاليكراي للمصعد. يمكنك البحث عبر الإنترنت بواسطة محركات البحث بكلمات مثل "دليل 16 مم تركي شاليكراي للمصعد" للعثور على المعلومات التي تبحث عنها. ي..

حالة التوفر:متوفر

دليل 16 مم صينى

EGP611.00

السابق الضرائب: EGP611.00

دليل 16 مم صينى أعتذر، ولكن لا يمكنني توفير دليل محدد بشكل فردي لمنتج معين بحجم 16 مم صيني للمصعد. يمكنك البحث عبر الإنترنت بواسطة محركات البحث بكلمات مثل "دليل 16 مم صيني للمصعد" للعثور على المعلومات التي تبحث عنها. يفضل مراجعة المواقع الرسمية ..

حالة التوفر:متوفر

دليل 16 مم مستورد

EGP405.00

السابق الضرائب: EGP405.00

دليل 16 مم مستورد أعتذر، لكن ليس لدي القدرة على توفير دليل محدد بشكل فردي لمنتج معين بحجم 16 مم مستورد للمصعد. يمكنك محاولة البحث عبر الإنترنت باستخدام محركات البحث بكلمات مثل "دليل 16 مم مستورد للمصعد" للعثور على المعلومات التي تحتاجها. يفضل ال..

حالة التوفر:متوفر

دليل 5 ملم - صيني سافيرا-90 × 62 × 5 ملم مع الفلنشـــة و المســــامير

EGP210.00

السابق الضرائب: EGP210.00

دليل 5 ملم - صيني سافيرا-90 × 62 × 5 ملم مع الفلنشـــة و المســــامير أعتذر، ولكن لا يمكنني توفير دليل محدد بشكل فردي لمنتج معين بحجم 5 ملم صيني من نوع سافيرا بأبعاد 90 × 62 × 5 ملم مع الفلنشة والمسامير للمصعد. يمكنك محاولة الاتصال بالشركة المصن..

حالة التوفر:متوفر

المصعد (1).jpg)